As far as I know, anyone that runs a 3D scanning studio for mini-figures, uses the

3D Systems 660 sandstone printer. While this printer is far from perfect, if you get the color right, it can produce nice results.

But are there any alternatives? Well, there are other "color 3D printers", but are any good enough to print mini-figures. A while back I already tried the color plastic 3d printer from stratasys, the Stratasys-j750. I unfortunately came very quick to the conclusion that the lack of color spectrum (only 360K colors) was a serious limit. Color difference between skin and light colored hair was really invisible. Skin tones where nowhere realistic. So "full color" plastic 3D printing, not an option.

There is one other technology that allows you to print in full color, using normal paper. This technology is used by the company Mcore. They have has a full color 3D printer for a while, the Mcor Iris and they have announced a new printer calles the Mcore Arke.. Especially that last one triggered our attention. The printer will be prices at around $8000, which seems very reasonable for a 3D printer.

The printer uses a normal inject printer to print each layer on a normal sheet of paper. This paper is then cut around the edges of the object and then qlued layer on top of layer. With the Iris printer, you have to separately print out the sheets of paper and then insert it in the Iris machine who will do the cutting and glue-ing. With the upcoming Arke printer, the inkjet priting part is integrated into the printer it self. It also prints just on a paper roll, instead of individual paper sheets.

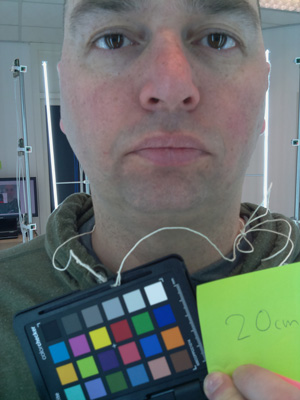

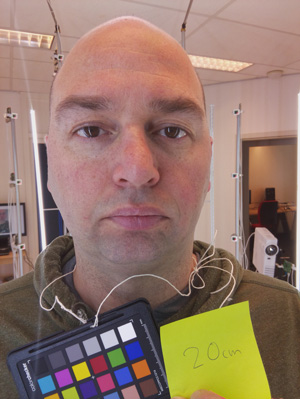

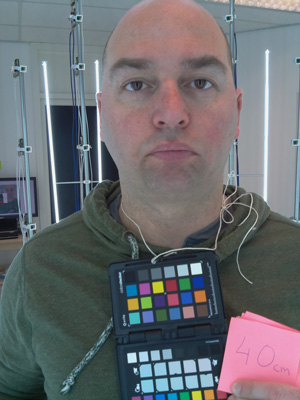

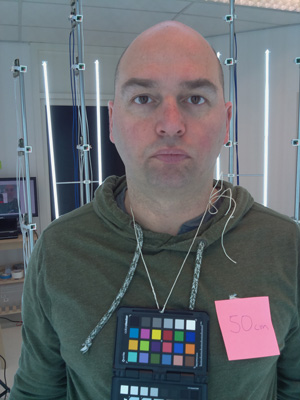

I had to try this paper printer technology, so found a company in germany called Formicum that was willing to print my 3D model on their Mcore iris printer. They have a minimum height of 20cm, so instead of printing my model in 1:10 scale, they upscaled it a little bit for me to reach their minimum size limit of 20cm. (I have no idea why they have this limit).

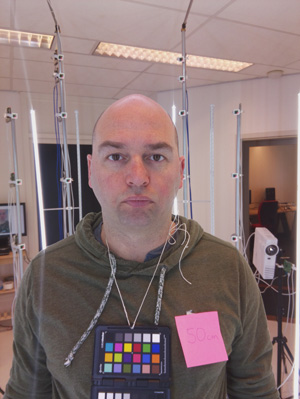

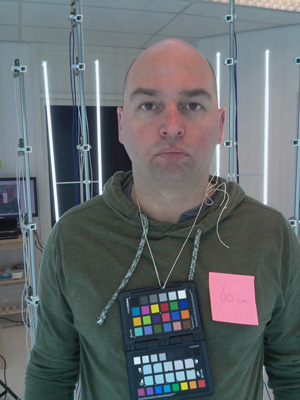

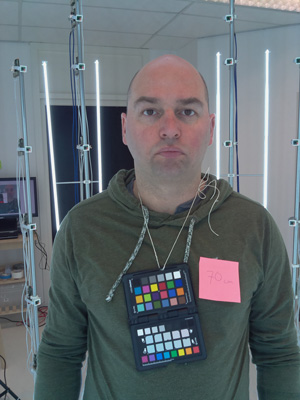

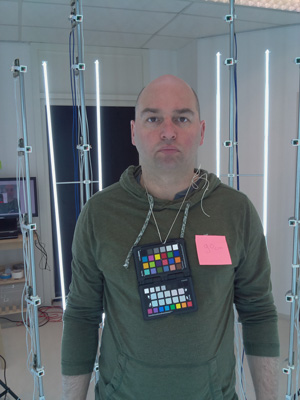

Here the results (compared to is sandstone counterpart):

I hope that the pictures are clean enough, but to my conclusion, this printing technology is clearly not suitable for priting 3D figurines. On the mcore website you will see that they state their printers are suitable for this and even show examples. If you look closely to their own examples (which I assume are the best possible prints) you also see the massive "color bleeding" cased by the fact that each layer is not very exactly glued on top of each other.

So for now, we will keep printing on the 3D systems project 660, while not perfect, unfortunately today our only option. There is starting to be competition in the market for the full color sandstone printers. For instance, made in china is the ComeTrue 3D printer. We have need been able to find a service that uses that printer, so if you have any experience with that printer, please let us know!